As the automotive industry marches towards a future defined by efficiency, performance, and sustainability, the evolution from 12V to 48V electrical systems signifies a pivotal transformation. This shift, driven by the necessity for smarter power management, promises to redefine how vehicles operate, integrate advanced technologies, and meet stringent environmental standards. In this article, we explore the impetus behind this transition and the benefits that 48V systems bring to the forefront of modern automotive engineering.

The Imperative for Change

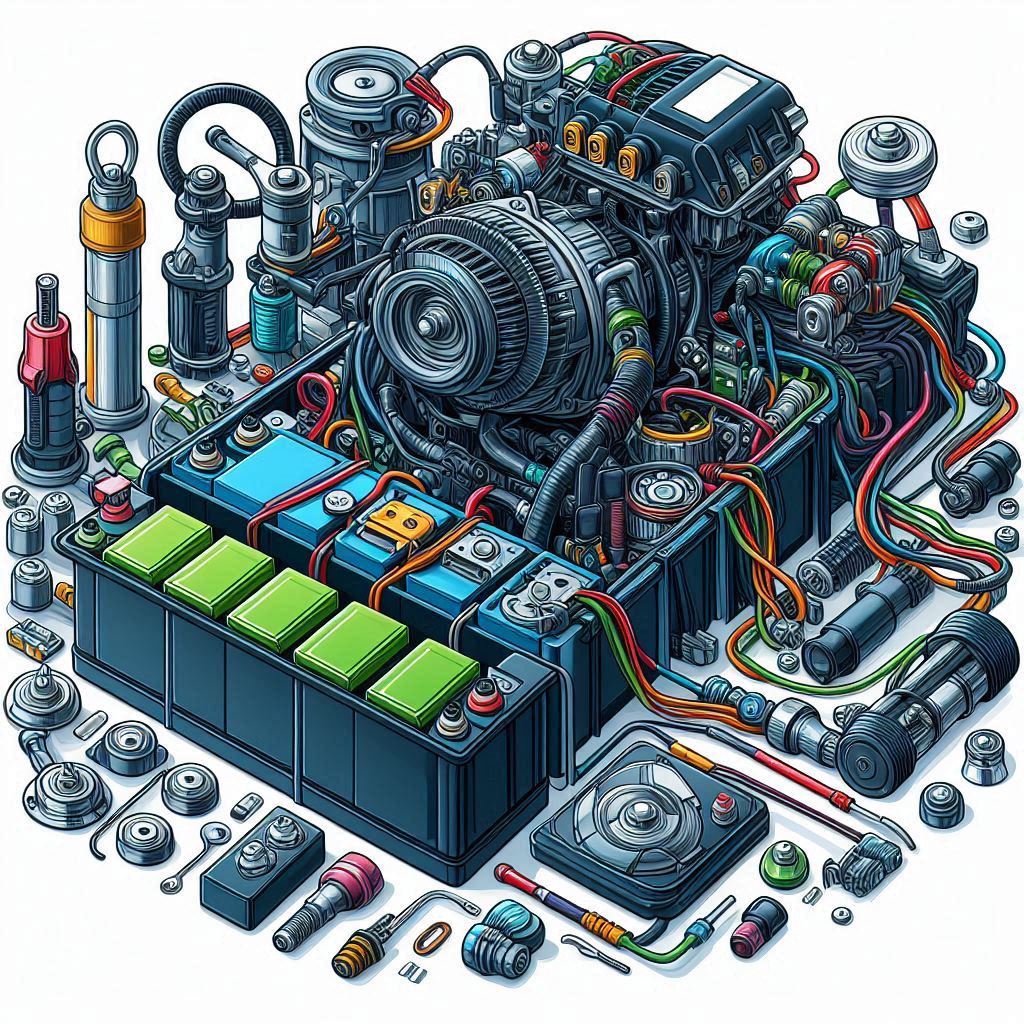

The rise of electric and hybrid vehicles, coupled with the proliferation of advanced driver-assistance systems (ADAS), infotainment, and other high-demand electrical components, has stretched the capabilities of traditional 12V systems to their limits. To sustain and enhance these innovations, the automotive industry is turning to 48V systems, which offer a superior platform for meeting the growing power requirements without compromising efficiency or safety.

Understanding Smart Power

Smart power in the automotive context refers to the intelligent management of electrical energy to optimize vehicle performance, reduce emissions, and enhance the driving experience. A 48V system exemplifies smart power by enabling more efficient energy distribution and supporting a range of advanced technologies that are critical for modern vehicles.

Advantages of 48V Systems

Enhanced Power and Efficiency

At the core of the shift to 48V systems is the need for greater power delivery with improved efficiency. As mentioned earlier, a 48V system can transmit more power with less current compared to a 12V system, reducing energy losses and heat generation. This efficiency is particularly beneficial for electric and hybrid vehicles, where energy conservation directly impacts vehicle range and fuel economy.

Weight and Space Savings

Reducing the current also allows for the use of thinner, lighter wires, which decreases the overall weight of the vehicle. This weight reduction contributes to improved fuel efficiency and performance. Additionally, with the ability to handle higher power loads, 48V systems enable more compact and efficient component designs, freeing up space for other innovations within the vehicle.

Supporting Advanced Technologies

The increased power capacity of 48V systems supports a wide range of advanced automotive technologies, including:

- Mild Hybrid Electric Vehicles (MHEVs): These vehicles utilize a 48V system to provide additional power to the internal combustion engine, improving fuel efficiency and reducing emissions.

- Regenerative Braking: The higher voltage allows for more effective energy recovery during braking, which can be stored and reused, enhancing overall efficiency.

- Electric Turbocharging: A 48V system can power electric turbochargers, providing improved acceleration and performance without the lag associated with traditional turbochargers.

- Advanced Driver Assistance Systems (ADAS): Features like active suspension, lane-keeping assist, and adaptive cruise control benefit from the higher power availability of 48V systems.

Cost and Safety Considerations

While the initial cost of implementing a 48V system may be higher due to the need for new components and infrastructure, the long-term savings in fuel costs, improved vehicle performance, and reduced maintenance can offset these expenses. Additionally, with proper design and safety measures, the higher voltage systems can be as safe as 12V systems. Enhanced insulation, protective devices, and careful engineering mitigate the risks associated with higher voltage.

Improved Reliability and Durability

The lower current flow in 48V systems reduces the stress on electrical components, potentially extending their lifespan and improving overall system reliability. This durability translates to fewer maintenance requirements and a longer operational life for the vehicle’s electrical system.

Looking Ahead: The Future of Automotive Electrical Systems

The transition to 48V systems is not just a technological upgrade; it represents a foundational shift towards smarter, more efficient power management in the automotive industry. As manufacturers continue to innovate, the adoption of 48V systems is expected to become more widespread, paving the way for the next generation of electric and hybrid vehicles, as well as advanced driver assistance and infotainment systems.

Conclusion

The evolution from 12V to 48V electrical systems marks a significant milestone in the journey towards smarter, more efficient automotive power management. By enabling enhanced performance, supporting advanced technologies, and improving overall efficiency, 48V systems are set to redefine the automotive landscape. As the industry embraces this transformation, vehicles will become more powerful, efficient, and environmentally friendly, driving us onward with smart power into a future of sustainable and innovative mobility.

To power 12V electrical equipment from a 48V battery, you can use a DC-DC buck converter. Here are the steps:

- Select a DC-DC Buck Converter:

- Ensure the converter can accept a 48V input and provide a 12V output.

- Check that the converter’s power and current ratings meet your 12V equipment requirements.

- Connect the Converter:

- Connect the 48V battery’s positive and negative terminals to the input terminals of the DC-DC converter.

- Connect the 12V equipment to the output terminals of the converter, ensuring correct polarity.

- Test the Setup:

- Turn on the 48V battery and measure the output voltage of the converter to ensure it is 12V.

- Connect your 12V equipment to the converter and verify it operates correctly.

Summary Diagram

48V Battery -> DC-DC Buck Converter -> 12V Electrical Equipment

Tips

- Efficiency: Choose a high-efficiency converter to minimize energy loss and heat.

- Cooling: Ensure adequate cooling for the converter if operating at high power.

- Safety: Double-check all connections and consider using fuses for protection.